The disassembly and assembly of the piston connecting rod assembly is an important and common maintenance item for diesel engines. The quality of its disassembly and assembly is directly related to the repair cost, working performance and service life, and the quality of its disassembly and assembly is closely related to the correctness of the disassembly and assembly method.The installation of the piston connecting rod assembly of the cylinder diesel engine can generally be divided into the assembly of the piston connecting rod assembly, the installation of the piston connecting rod assembly on the diesel engine, and the alignment of the piston in the cylinder. As a turbine manager, you must be proficient in the disassembly, assembly and inspection methods of piston connecting rod components.

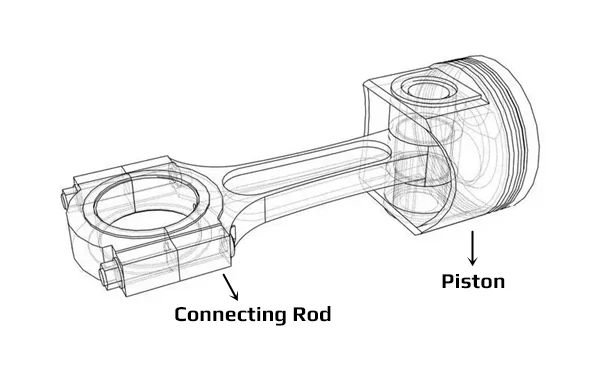

The piston assembly and connecting rod assembly are the main moving parts of the diesel engine. For barrel-type diesel engines, these two parts are usually connected by floating piston pins to form a moving whole – a piston connecting rod mechanism. When disassembling and assembling, the whole unit is dismantled and used out or hoisted in for installation. The crosshead diesel engine is connected through the crosshead assembly. When disassembling and assembling, disassemble and lift out or lift in for installation.

Disassembly steps

1.Preparation

Before disassembly, clean the oil and carbon deposits on the upper part of the cylinder liner and the piston top, and then perform the following inspections and repairs on the cylinder liner and piston top:

(1) Treatment of red sleeves: There are usually wear bosses on the new sleeve corresponding to the first ring when working at the top point. Obvious signs of wear can be found through physical observation. You can easily find out by touching the mold with your hands. Worn boss. This boss is easy to get stuck on the piston ring and pull it off when the piston is lifted out. Therefore, before lifting the cylinder, it should be scraped off with a triangular scraper to make it a transitional bevel, and then polished smooth with a whetstone to eliminate scraping marks.

(2) Live sub-processing: Check and trim the piston lifting holes. After clearing the carbon deposits in the guard holes, observe the thread condition. If there is damage or hard carbon deposits that are difficult to remove, you can use a tap with the same specifications as the pre-hole blasting to restore the threads.

2.Remove the connecting rod big end bearing cap

(1) Crank to the top dead center or the angle required by the instruction manual, and pull up canvas from both sides of the tunnel door under the crank pin to prevent foreign matter falling during the cylinder lifting process from contaminating the crankcase.

(2) Install the piston lifting tool on the piston ceiling mounting hole and hang it on the hook of the lifting equipment to lift it gently but do not tighten it.

(3) Check and confirm the assembly marks of the upper and lower tiles from the doors on both sides. Usually the marks are marked on the control side tile shell.

(4) Disassemble the connecting rod nut locking device. If it is a cotter pin or locking wire, it can be removed directly. If it is a locking piece, the iron piece can be straightened.

(5) Use a torque wrench to loosen the nut several times or install the hydraulic tensioner as required and perform oil flushing and deflation and other preparations, then use a manual pump to pump oil to the specified pressure, and then use a dial pin to loosen the nut by about half lock up. Release the oil pressure and remove the hydraulic tensioner.

(6) Cover the bearing cap with a square piece of wood, unscrew the nut and take out the bearing cap and bearing bush. For faceted bearing caps that are disassembled and assembled using a hydraulic stretching tool, it is often necessary to remove two studs before the lower part can be taken out from the door. watt,

(7) Lift out the piston connecting rod assembly.

(8) Adjust the position of the hook so that it is on the extension line of the cylinder axis, lift the piston slightly and lower the upper shoe lining.

(9) Take out the upper tile village, and then use tape to seal the oil hole on the crank pin to prevent the guide material from falling into the oil passage. If it is a connecting rod with a three-section structure, you can insert a black hammer on the side of the upper tile to remove the lower bearing. The cover is fixed on the connecting rod bolt, and then the connecting surface of the connecting rod and the upper bearing is opened. After the piston is lifted out, the big end bearing of the lower connecting rod is taken out.

(10) Slowly lift out the piston connecting rod assembly from the upper part of the cylinder. When lifting out, someone must guard the tunnel door and check the position of the big end of the connecting rod at all times to avoid hanging on the bottom of the cylinder liner and damaging the machine parts.

(11) Lift out the piston assembly and place it on the movable frame. After simply cleaning the big-end bearing, assemble the bearing cap to the connecting rod as originally intended to avoid confusion of parts.

Assembly steps

1. Preprocessing of parts

(1) Crank pin:

After removing the tape that seals the oil hole and cleaning it thoroughly, apply a thin layer of clean engine oil on the shaft and then crank to the top dead center. If the big end of the connecting rod has an oblique cut, it should be cranked to slightly before the top dead center.

(2) Cylinder liner:

After thorough cleaning, apply a thin layer of clean engine oil to the working surface, then install a guide sleeve on the top surface of the cylinder liner and apply clean engine oil.

(3) Piston connecting rod assembly:

Install the lifting tool on the lifting hole on the top surface of the piston, lift the assembly slightly off the ground, and use the piston ring tool to install the piston rings one by one from both ends of the assembly.

(4) Connecting rod bearing:

After thoroughly cleaning the bearings, apply a thin layer of clean engine oil on the mating surface of the base and the back of the upper and lower tiles; install the upper and lower tile villages into the upper and lower tile seats respectively. At this time, the tile village positioning protrusions should be in place correctly.

(5) Connecting rod bolts and bolt holes:

After thoroughly cleaning the connecting rod bolts and bolt holes, apply a thin layer of clean engine oil on their positioning surfaces and bolt head supporting surfaces, and apply a thin layer of clean engine oil on the threads.

2. Install the piston connecting rod assembly into the cylinder

(1) Use the assembly above the cylinder, adjust the position of the car so that the piston axis is on the extension line of the cylinder axis, and then make the following preparations: arrange the movable ring so that the adjacent overlaps are opened 120 degrees, and apply paint on the ring surface and the piston surface Apply a layer of clean engine oil; check the assembly mark on the big end of the connecting rod and adjust it to the correct position.

(2) Slowly lower the piston assembly and guide it into the cylinder liner through the guide sleeve hole. At this time, pay attention to aligning the upper bearing of the connecting rod to sit on the crank pin at the gate. Note: If the piston is stuck by a certain ring during the falling process and cannot fall, At this time, the piston top cannot be hard loosened. You can only press the guide sleeve and slightly raise the assembly to adjust the stuck piston ring and then try to lower it.

3. Assembly of connecting rod and crank pin

(1) Assembly of bearing cap

Turning to the top dead center: Apply a layer of clean engine oil to the working surface of the tile cover and install it on the crank pin according to the original assembly mark. Then insert the connecting rod bolt into the connecting rod bearing bolt hole and install the nut.

(2) Tighten the connecting rod nut

Apply a layer of clean engine oil to the nuts and bolts and tighten the nuts according to the required tightening torque or pressure. Note that if a cotter pin is used for locking, the pin hole should be aligned while tightening, so as not to miss the opportunity. If it goes too far, you can only unscrew the nuts on both sides and retighten the opposite holes, because this will destroy the bearing clearance on one side, and secondly, it will bring excessive additional stress to the bolt.

(3) Check the assembly quality and tighten the anti-loosening device

Check the assembly quality by turning and turning. It should be that the fitting parts can rotate flexibly and freely without any stuck phenomenon or abnormal noise. After the inspection is correct, lock the anti-loosening device. When locking with a cotter pin, the short side of the pin should be folded towards the thread head. Shadow, fold the long side toward the corresponding hexagonal edge of the nut. It is not allowed to fold the two sides of the cotter pin around the nut.

(4) Take out the tools and application materials in the crankcase, check if they are correct, clean the crankcase thoroughly, and reinstall the access door after confirming that they are correct.

(5) Find the roundness value and cylindricity value.

(6) After measuring the piston pin seat hole and the small end of the connecting rod, the fit (or interference) between the piston pin, the connecting rod small end bearing and the seat hole can be calculated.

(7) If the roundness and cylindricity exceed half of the piston pin diameter tolerance, the fit between the piston pin, the seat hole and the small end bearing of the connecting rod reaches the specification limit, or the carburized layer on the surface of the piston pin falls off, cracks, etc. Defects should be replaced or repaired. When repairing, surface grinding and chrome plating are allowed to restore the dimensions.

4. Inspection of piston rings

(1) To check the piston ring end clearance, first place the piston ring flatly in the cylinder to be matched, use the piston head to push the piston ring flatly into the cylinder about 10cm, and then use a feeler gauge to insert the piston ring opening to measure. Usually the end gap of the first air ring of the engine is 0.2~0.32mm, and the end gap of the second air ring is 0.30~0.50mm.

(2) Measurement and inspection of ring groove side clearance

The side performance of Huanbo means that the piston is broken in the upper and lower spaces in the sugar, or it is called the end-to-end court. If the side chamber is too large, it will affect the sealing effect of the piston. If it is too small, the piston will be damaged and stuck in the replacement during operation. During inspection, put the piston ring into the valve and measure and inspect it using the thinning method. If the side is too small, place the piston ring on the back of the fine emery cloth and place it flat on the glass plate (glass plate) for grinding, grinding and matching until it presses until the gap specified in the instruction manual.

(3) Inspection of piston ring gaps

Put the movable ring into the movable ring groove. The piston ring should be lower than the piston ring land (0.200.35) m to avoid getting stuck in the steam during operation. Usually the gas ring groove is (0.150.35) mm and the oil ring is (0.35~ 0.70

mm.

(4) Inspection and trimming of the piston ring closing clearance and end face axial clearance must be done to prevent the ring from being stuck in the ring after expansion, which must be verified during installation. Observe the accuracy of the opening and closing space and the incoming and outgoing space of the end face. If the closing space is too small, use a knife to trim it. During trimming, the fittings should be tightly closed and the sharp edges should be deburred to prevent the cylinder wall from being scratched after installation.