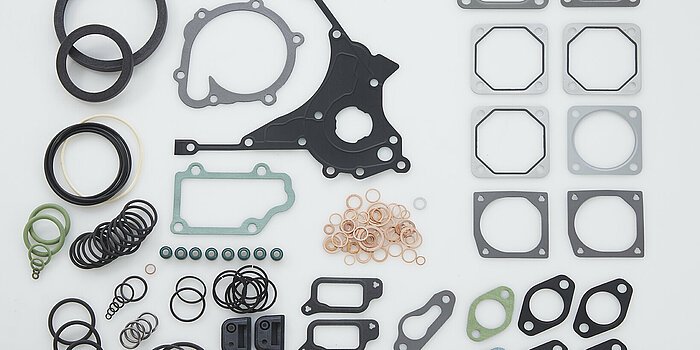

In the field of mechanical manufacturing and engineering, gaskets are a common part, they are usually used to fill or cleanFill the gap between the two objects to achieve sealing, cushioning, seismic, anti-slip and other purposes. Gaskets can be metal Made of rubber, plastic and other materials, the shape can also have a variety of changes. This article will introduce the role of the gasket and its role in notMade of rubber, plastic and other materials, the shape can also have a variety of changes. This article will introduce the role of the gasket and its role in notApplication in the same scenario.

sealing function

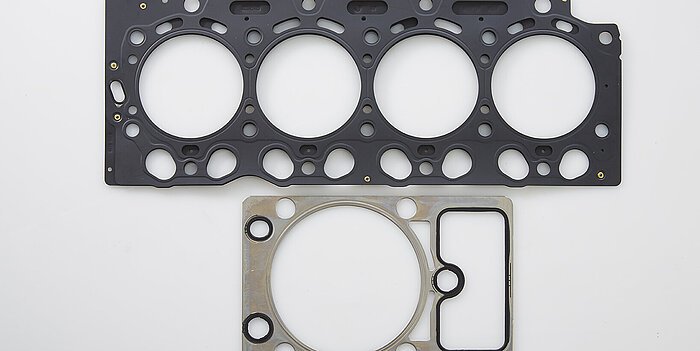

- The most common role of gaskets is to achieve sealing. When two mechanical parts are connected, due to manufacturing and processing

Imprecision, often resulting in tiny gaps in the joints. These gaps can lead to liquids, gases and even dust

Leakage, thus affecting the normal work of the equipment. The main role of the gasket is to fill these gaps to form an effective

Seal layer to prevent leakage.

Gaskets are often used in pipe connections, valves, pumps and other equipment to ensure sealing effect. Gaskets are usually made of soft

Made of soft materials, such as rubber or flexible metal, able to adapt to the imperfect shape of the joint and shape under pressure

Form a tight seal.

buffer action

Another important role of the gasket is cushioning. In mechanical devices, many parts are usually made of metal or hard materialsMaterial composition, when they come into contact with each other or are impacted, may cause excessive stress concentration. Gaskets can be madeTo cushion the material, disperse the impact force and reduce the concentration of pressure between parts, thereby protecting the equipment from excessive damageEspecially in the suspension system of automobiles and mechanical equipment, gaskets are widely used. They disperse and suckAbsorbing vibration and impact force can make the equipment run more smoothly and extend its service life.

The gasket can also provide anti-slip function. In some applications where parts need to be prevented from sliding relative to each other, gaskets are usedUsed to increase the coefficient of friction, thereby enhancing the stability of the connection. For example, in furniture manufacturing, gaskets are often usedTo increase the coefficient of friction,Thereby enhancing the stability of the connection.

For example,

In furniture manufacturing,Gaskets are usually used

Furniture soles to prevent furniture from sliding on the ground, providing better stability and security,

In addition, gaskets can also be used to reduce noise and vibration. When mechanical equipment is in operation, all kinds of noise will be generatedSound and vibration, causing disturbance to the operator and the surrounding environment. Gaskets can reduce noise by absorbing and reducing vibrationSound level, creating a quieter and more comfortable working environment.In the fields of elevators, engines and large mechanical equipment, gaskets are often used as vibration damping gaskets to reduce the vibrationThe effect of mechanical vibration on the surrounding environment and the equipment itself.

Other Applications

Gaskets have many other applications. For example, in the assembly of electronic devices, gaskets can be used to fill

Gap between circuit board and housing to provide electrical insulation and dust proof effect. In food processing and pharmaceuticals,

Gaskets are used for sealing and protecting food and medicine to ensure product quality and safety.

In addition, in the aerospace, Marine and chemical industries, gaskets also play an important role for support and protection

To protect and ensure the safe and reliable operation of all components of aircraft and ships,

Conclusion

Gasket, as a common mechanical part, plays an important role in all walks of life. Their workIt can include sealing, buffering, anti-slip and noise reduction, etc., which provides guarantee for the normal operation and long-term use of the equipment. Along with the

With the development of technology and the continuous expansion of application scenarios, the types and materials of gaskets are also constantly innovating and improvingTo meet complex and demanding application needs,